How to make the most of research

BUSINESS VIEWPOINT DUNCAN DAVIES

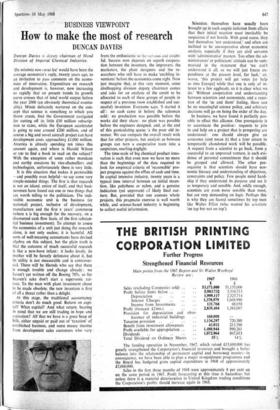

Duncan Davies is deputy chairman of Mond Division of Imperial Chemical Industries. •

'De minimis non curat lex' would have been the average economist's reply, twenty years ago, to an invitation to pass comment on the econo- mics of innovation. Expenditure on research and development is, however, now increasing so rapidly that on present trends its growth curve crosses that of total world output before the year 2000 (an obviously theoretical eventu- ality). Minds delicately nurtured on the con- cept that science is something to which you throw crusts, find the Government castigated for cutting off its little £10 million subscrip- tion to ELDO, while the European accelerator is going to cost around £200 million, and of course a big and novel aircraft project can have development costs approaching £1,000 million. America is already spending ten times this amount again, and where is Harold Wilson or LBJ to find a book to read on the subject? With the exception of some rather mundane and earthy creations by vice-chancellors and technologists, unfortunately there, is very little.

It is this situation that makes it permissible —and possibly even helpful—to say some very simple-minded things. The first is that research is not an island, entire of itself, and that busi- nessmen have found out one or two things that are worth telling to the politicians. The indi- visible economic unit is the business (or national) project, inclusive of development, manufacture and the first x years' commerce (where x is big enough for the recovery, on a discounted cash flow basis, of the first substan- tial business investment). To attempt to assess the economics of a unit just doing the research alone, is not only useless; it is harmful. All sorts of well-meaning accountants have devised algebra on this subject, but the plain truth is that the outcome of much successful research is like a new-born infant: it looks lovely, its mother will be fiercely defensive about it, but its utility is not measurable and is controver- sial. There will be Herods who say that there is enough trouble and change already: we haven't yet written off the Boeing 707s, so for heaven's sake don't start a supersonic rat- race. To the man with plant investment about to be made obsolete, the new invention is first of all a threat rather than a delight.

At this stage, the traditional accountancy criteria don't do much good. Return on capi- tal? What capital? And what return, bearing in mind that we are still trading in hope and aspiration? All that we have is a great heap of bills, either unpaid or paid out of 'taxation' of established business, and some mousy income from development sales customers who vary from the enthusiastic to the nerNous and doubt- ful. Success now depends on superb coopera- tion between the inventors, the improvers, the marketers, the plant designers and the re- searchers who still have to make 'enabling in- ventions' before the economics come right. Now just imagine that, at this very moment, some clodhopping division deputy chairman comes and asks for an analysis of the credit to be allocated to each of these groups of people in respect of a previous (now established and suc- cessful) invention. Everyone says, 'I started it all': no cash came in before the salesman sold: no production was possible before the works did their share: no plant was possible before the engineers designed, and, at the end of this gesticulating queue :s the poor old in- ventor. We can compare the overall result with that for other projects, but analysis as between groups can turn a cooperative team into a suspicious, snarling dogfight.

The time-scale of big chemical product inno- vation is such that even now we have no more than the beginnings of the data required to look for empirical criteria of 'reasonable' pro- ject progress against the efflux of cash and time. In capital intensive industry, twenty years is a typical time interval between an initial inven- tion, like polythene or nylon, and a genuine indication (yet unproven) cf likely final out- turn. But, provided that one assesses whole projects, this pragmatic exercise is well worth while, and science-based industry is beginning to collect useful information. Scientists themselves have usually been brought up in such aseptic isolation from affairs that their initial reaction must inevitably be suspicious if not hostile. With good cause, they feel themselves 'not understood,' and often are inclined to be uncooperative about economic analysis, especially if they are civil servants with 'administrative' masters. Too often the ad- ministrators' or politicians' attitude can be sum- marised in the statement that 'we can't understand it all, so we will just freeze ex- penditure at the present level, for luck,' or, worse, 'this project will get votes [or help us into Europe] while that one is only of in- terest to a few eggheads, so it is clear what we do.' Without cooperation and understanding between scientists and economists, and a rejec- tion of the 'us and them' feeling, there can be no meaningful science policy, and arbitrary decisions will go on being the order of the day.

In business, we have found it perfectly pos- sible to effect this alliance. One prerequisite is to accentuate the positive: requests to join in and help on a project that is prospering are understood: one should always give an assurance (and mean it) that a later return to temporarily abandoned work will be possible. A request from a scientist to go back, from a successful to an unproved venture, is such evi- dence of personal commitment that it should be grasped and allowed. The other pre- requisite is that scientists should have eco- nomic literacy and understanding of objectives, constraints and policy. Few people mind hard- ship if they understand its purpose and see it as temporary and sensible. And, oddly enough, scientists are even- more sensible than most, but are very demanding on logic. Perhaps this is why they are feared sometimes by top men like Walter Elliot (who wanted his scientists 'on tap but not on top'). With retrospective analysis so difficult, how about the future planning of research and its associated other investments? Here, one needs to distinguish between two types of research activity in both of which good science can be deployed. The first, often called 'optimisation,' involves the use of science—perhaps the very latest and most sophisticated theoretical con- cepts—to improve the performance of known processes and existing plant assets. Here the objective is clear—lower cost and improved utility—from either quality improvement or product diversification. Research on the mechanism of manufacturing processes can show how to cut down unwanted side reactions (thus improving material efficiency) or how to speed things up (thus reducing capital charges). Optimisation can be planned by the use of very high-grade applied logic, in which relatively simple and cheap computer techniques are most useful. In an advancing industry, it pays for its costs many times over, and if one adds together the optimisation necessary to utilise an inven- tion economically, and the optimisation that it is reasonable to do on the existing business and technology, this will consume far more scientific effort than the inventive research that starts it all off—even including the attempted invention that fails. So the part of industrial science aimed at improving established business is a very reasonable risk.

When one turns to innovation, and the invest- ment decisions in backing new products and processes, life is very much more difficult. At present, the best counsel is to seek technical people for the quality of whose economic judg- ment there is past evidence: although this sounds poorish counsel, it is redeemed by the fact that successful innovation pays well enough to carry a good deal of concomitant failure. But the history of major product invention is more of brilliant recognition of the economic potential of unexpected experimental results than of highly logical attack on clearly recog- nised 'market objectives,' and it is this that makes it so necessary to assemble the technical and economic awareness within a single person. When the invention has been developed to the point of good technical and economic feasi- bility, there are the bigger risks of plant and commercial investment to be faced. These risks call for the same sort of semi-intuitive qualities, and indeed so do the risks involved in any com- petitive, capital-intensive plant building exer- cise, when the investment requires several years for its recovery. One is confronted, in the form of a predictive DCF, with year by year putative sales volume, realisations, plant costs, and capa- city occupation. Not all the mammoth com- puters in the world will let one off the hook of looking at these numbers and deciding subjec- tively, on the basis of experience, if they are plausible. And one must especially beware of procedures that present apparent assessments of risk which, sweeping the assumptions under the carpet, appear to diminish the need for critical judgment. One must look possible disaster in the eye, with little more than very unsophisticated arithmetic to help. The basic need is not for high-powered mathematics, but for reference data on the factors that truly distinguished be- tween the promising inventions that society agreed to buy eagerly enough to provide profit, and those on which society wasn't keen enough. It is for this reason that it is philosophy and general sociology, just as much as science, engineering and economics, that provide the uncomfortable filling for the industrialist's miduight pillow.

Previous page

Previous page